Engineering

The Impossible

Beyond Aerodynamics

OBSIDIAN X1

Precision • Power • Perfection

Powertrain & Propulsion

Tri-Motor E-Core

The Obsidian X1 utilizes a bespoke Tri-Motor Axial Flux architecture. Dual independent rear motors provide precise torque vectoring, while a high-density front motor ensures superior turn-in response and regenerative efficiency.

Configuration

Tri-Motor AWD

2 Rear (Ind.), 1 Front

Peak Output

1,450 HP / 1,080 kW

Overboost Mode

Total Torque

1,850 Nm

0-100% in 5ms

Power Density

8.2 kW/kg

Segment-leading efficiency

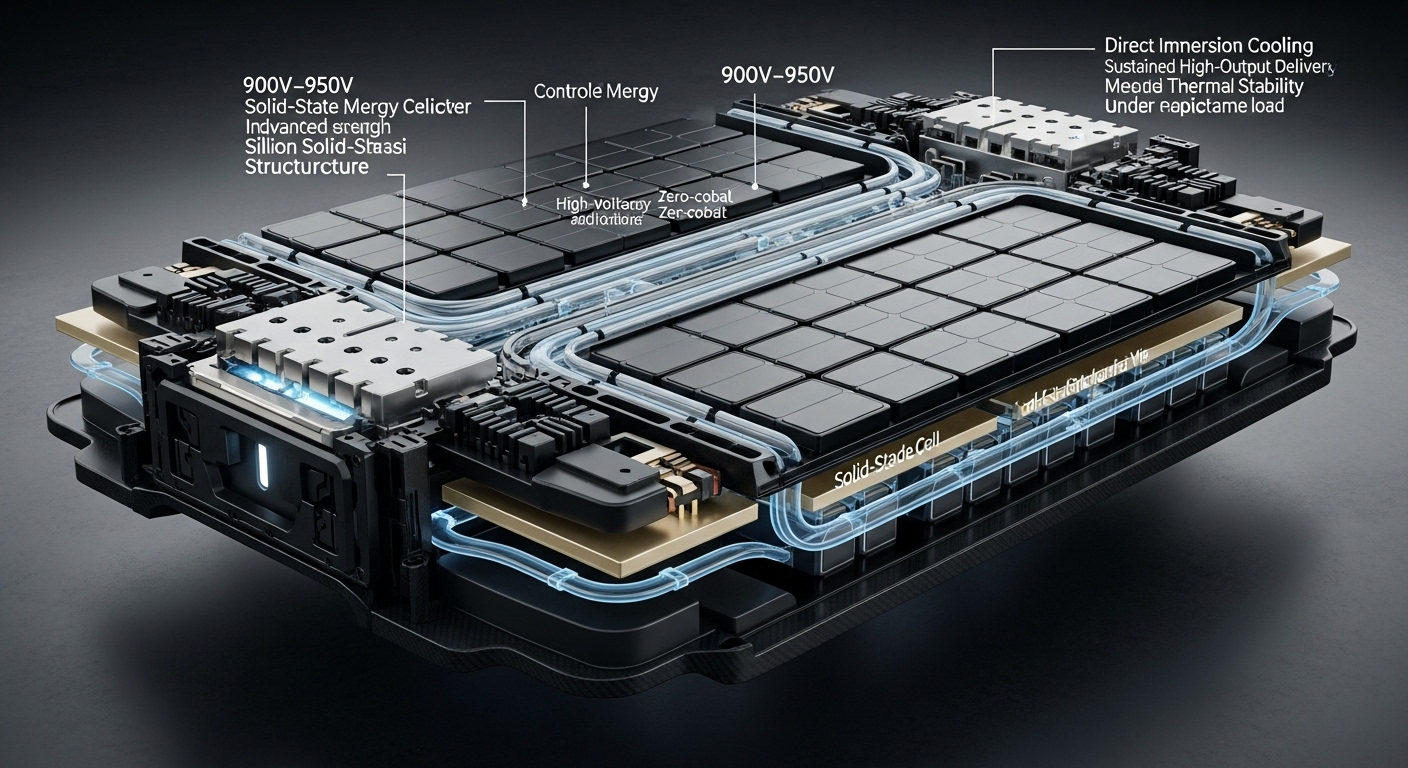

Energy Storage

Solid-State Matrix

Next-generation Silicon-Anode Solid State cells form the backbone of the X1. Integrated directly into the chassis (Cell-to-Chassis), the pack offers unparalleled structural rigidity while minimizing weight.

Chemistry

Silicon-Anode Solid State

Zero-Cobalt formulation

Charging

900V Architecture

10-80% in 12 mins

Thermal

Direct Immersion Cooling

Dielectric fluid management

Voltage

950V Peak

Sustained high-output delivery

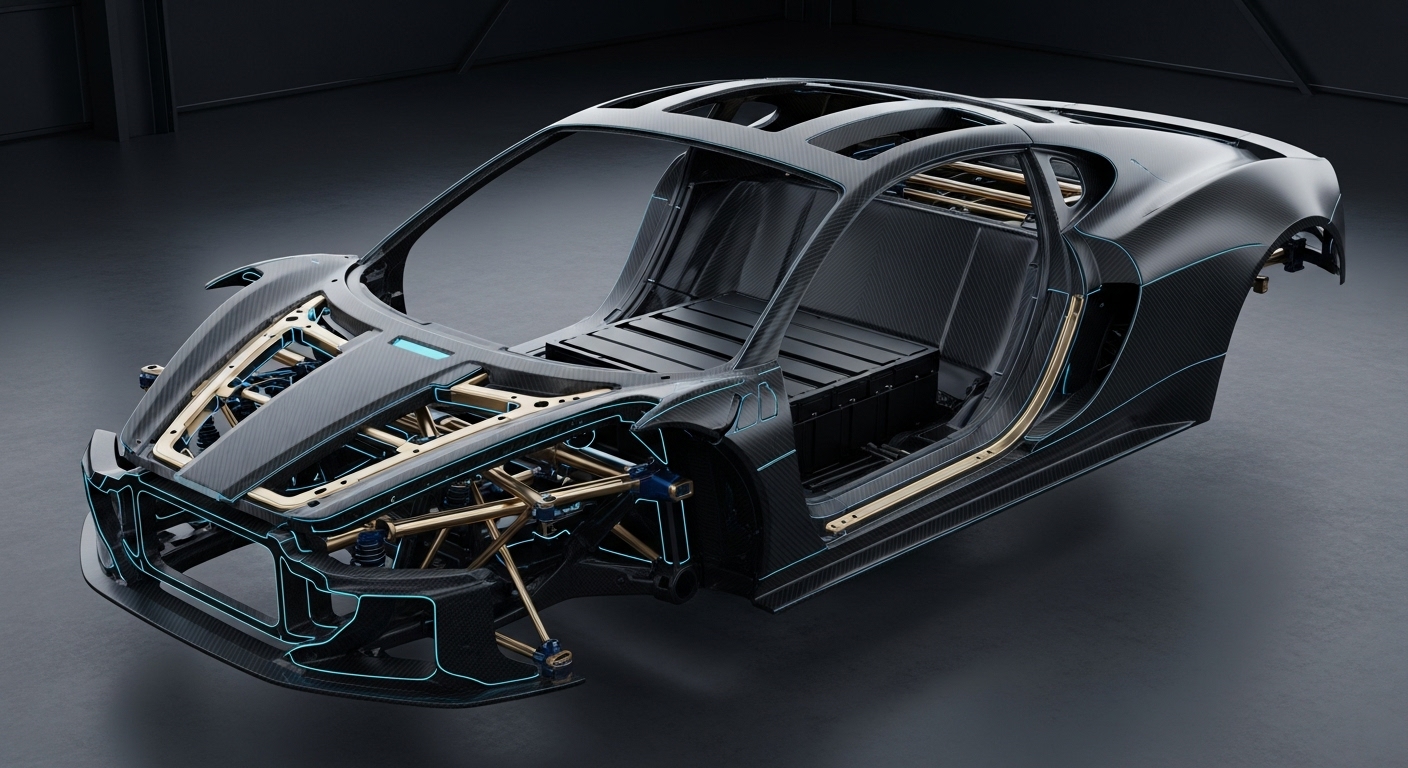

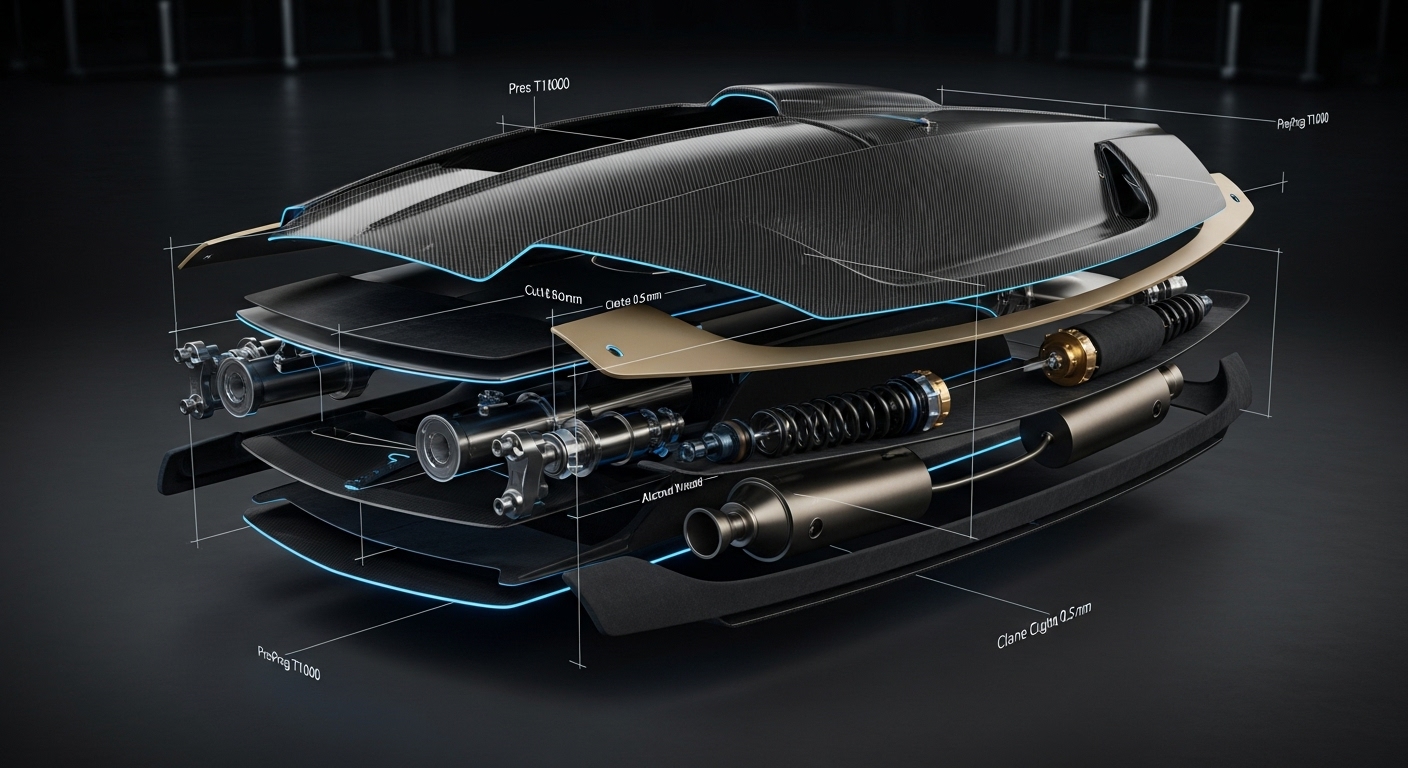

Chassis & Monocoque

Carbon-Titanium Weave

The central tub is a single-piece Carbo-Titanium Monocoque, weighing just 85kg. Utilizing aerospace-grade bonding, it integrates the battery structure as a stressed member to achieve F1-levels of torsional rigidity.

Structure

Carbo-Titanium Monocoque

Grade 5 Titanium inserts

Rigidity

65,000 Nm/deg

Torsional stiffness

Weight

85kg

Excluding subframes

Safety

FIA LMP1 Spec

Crash energy absorption

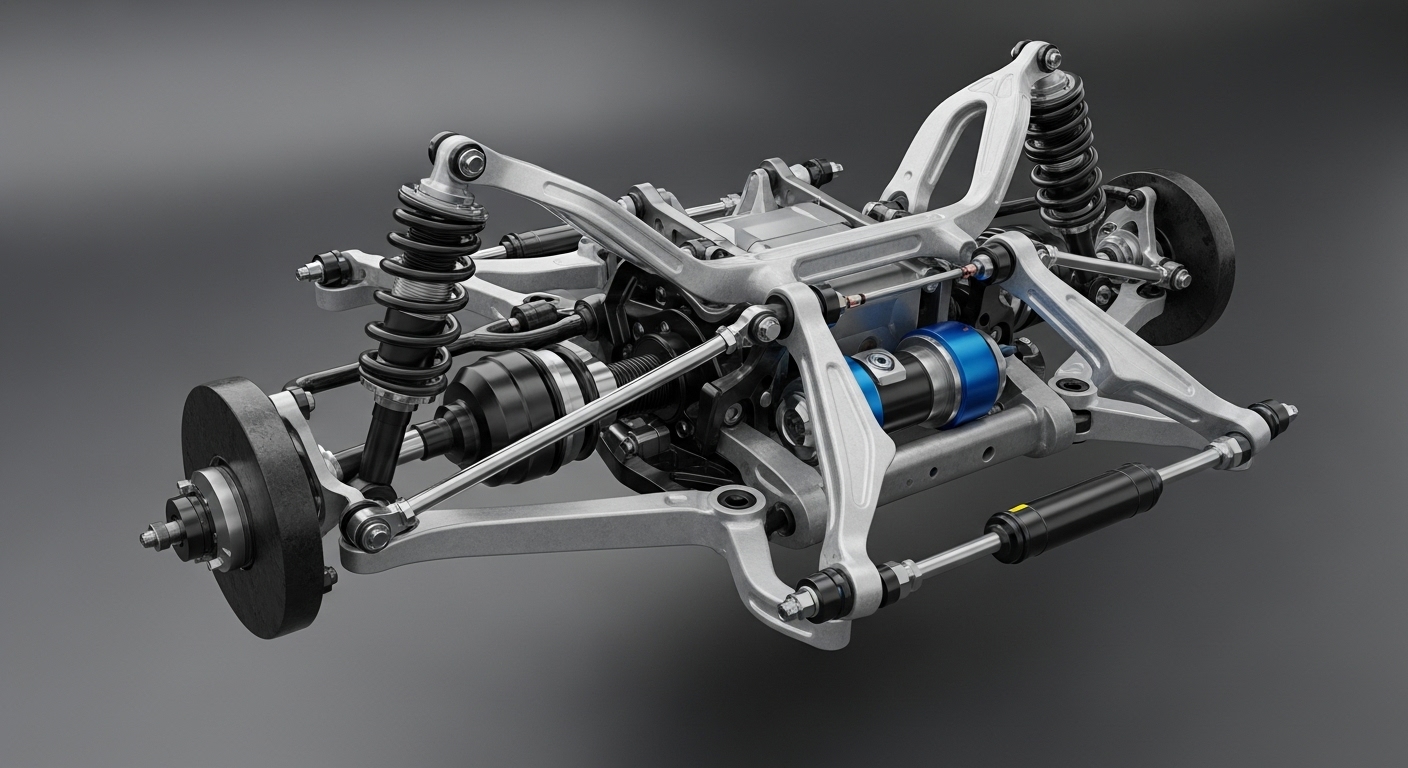

Suspension & Handling

Adaptive Push-Rod

Type

Active Push-Rod

Inboard dampers

Damping

MagneRide 4.0

1000 adjustments/sec

Ride Height

Variable (+/- 50mm)

GPS-linked auto-lift

Modes

Track / GT / Drift

Software-defined geometry

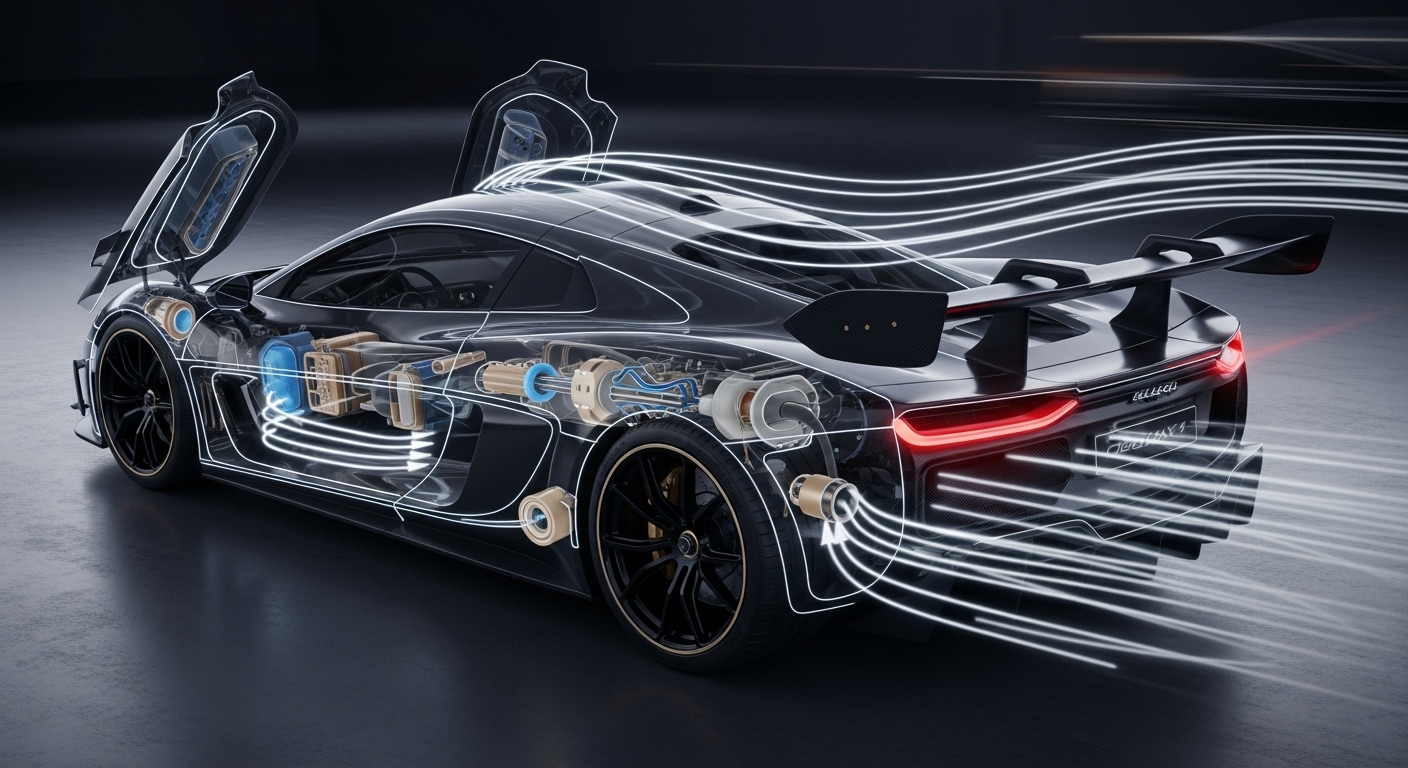

Aerodynamics

Active Flow Control

The X1 breathes with the road. Active front flaps and a dynamic rear wing work in unison to balance low-drag efficiency with massive cornering downforce.

Drag Coeff.

0.22 Cd

In VMAX Mode

Downforce

1,200 kg @ 250km/h

Active wing deployment

System

ALA (Active Aero)

Vectoring air flaps

Management

Internal Ducting

Through-body airflow

Braking System

Carbon-Ceramic Matrix

Material

CCM-R Discs

420mm Front / 390mm Rear

Calipers

Titanium Monobloc

10-piston front / 8-piston rear

Regen

0.4g Decel

Up to 300kW recovery

Temp Limit

1,200°C

Fadeless performance

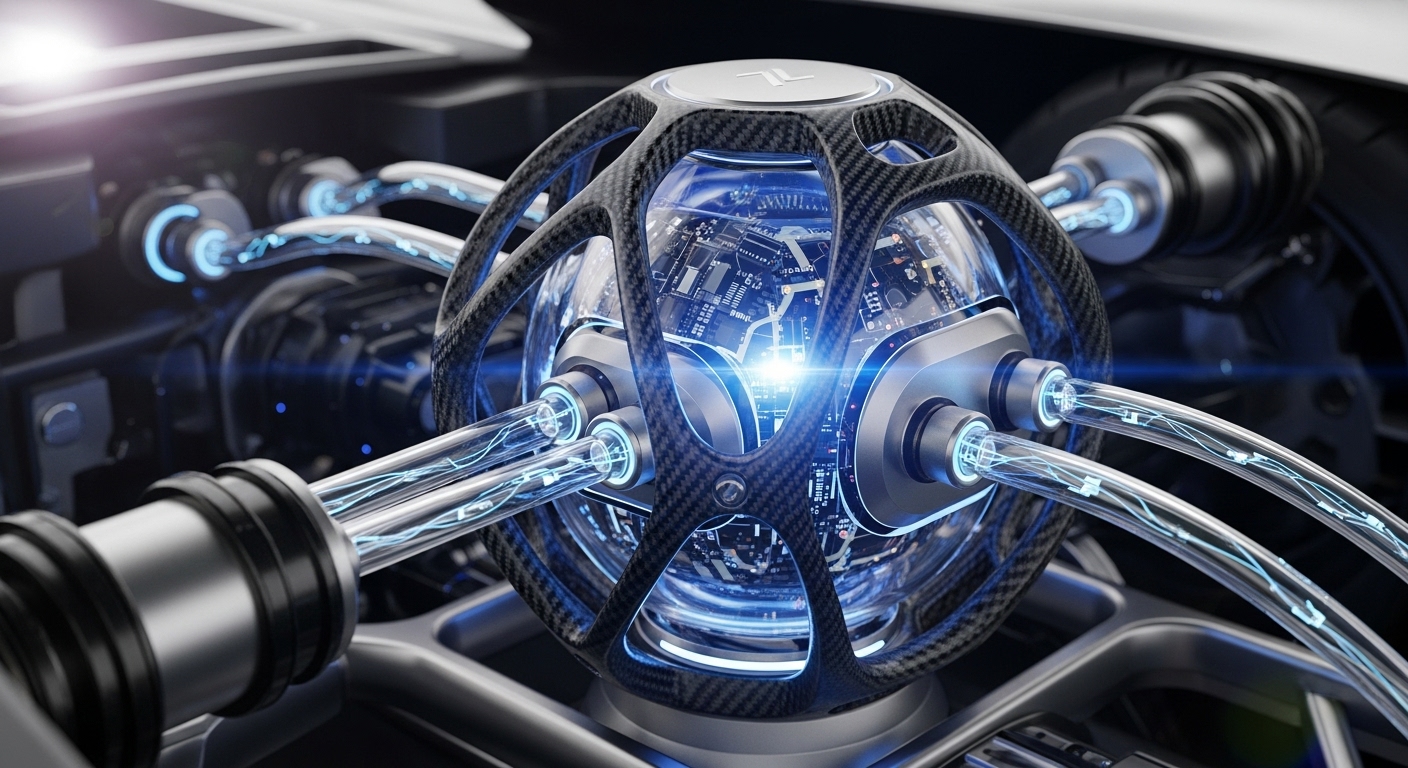

Electronics & Control

Neural Core

Architecture

Zonal Compute

Ethernet backbone

Processing

250 TOPS

Dual AI Accelerators

Fusion

Lidar + Radar + Vision

360° situational awareness

Update

Global OTA

Continuous drive-train optimization

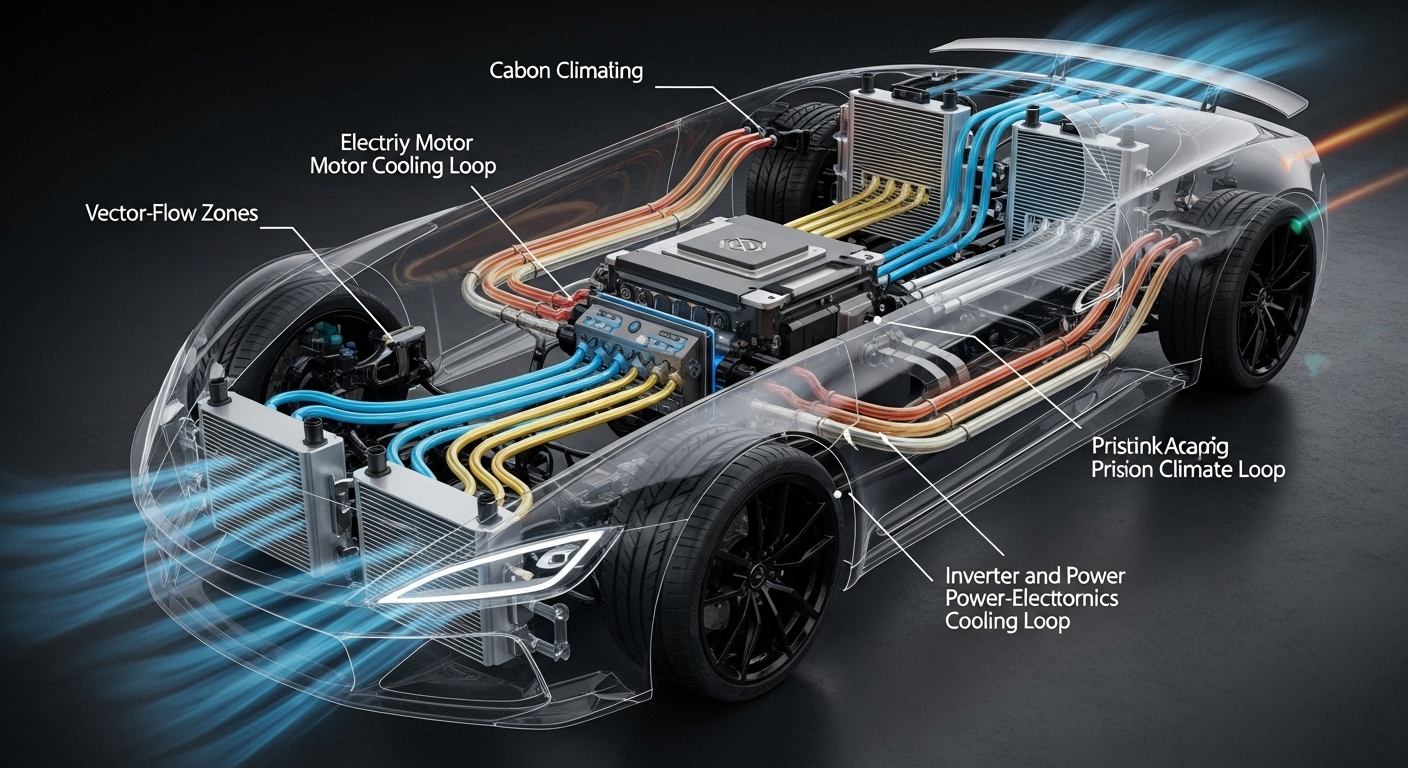

Thermal Systems

Cryo-Flow Management

Loops

4 Distinct Circuits

Battery, Motors, Inverters, Cabin

Radiators

Vector-Flow Radiators

Low-drag positioning

Logic

Predictive Pre-Cooling

GPS-based track anticipation

Heat Pump

Octovalve System

Waste heat scavenging

Materials & Manufacturing

Exotic Composition

Primary

Pre-preg Carbon Fiber

T1100 Grade

Metals

Inconel & Titanium

Exhaust & Suspension

Interior

Alcantara & Carbon

Sustainable vegan options

Precision

0.5mm Tolerance

Laser-scanned assembly

Safety & Reliability

Guardian Cell

Monocoque

Driver Survival Cell

F1 Safety Standards

High Voltage

Pyro-Fuse Isolation

2ms cut-off time

Testing

2M km Validated

Arctic to Desert conditions

Redundancy

Triple-Redundant

Critical control systems

Part 1 — Chassis

Structural

Monocoque

Inside the Machine — Chassis

Engineering the Core

The Obsidian X1 is built around a philosophy of absolute rigidity and integration. The chassis is not just a frame; it is the central nervous system of the vehicle, connecting power, control, and safety in a unified carbon-titanium structure.

Carbon-Fiber Monocoque

T1100 Grade CarbonA single-piece structural tub designed for F1-grade safety and rigidity, weighing only 85kg while bearing all primary loads.

Structural Rigidity

Zero FlexEngineered for maximum torsional stiffness (65,000 Nm/deg), ensuring suspension geometry remains precise under extreme cornering forces.

Low Center of Gravity

Sub-Axle CGThe battery acts as a stressed member at the lowest point of the chassis, keeping the center of mass well below the wheel axles for planted stability.

Crash Safety

FIA LMP1 SpecFront and rear impact structures utilizing varying modulus carbon fiber to control deformation and dissipate energy away from the driver cell.

Powertrain Integration

Stressed MemberDirect mounting of the tri-motor assembly to the subframes reduces mechanical loss and increases immediate torque transfer to the road.

Precision Manufacturing

0.5mm ToleranceLaser-aligned layup process with vacuum infusion ensures consistent resin distribution and eliminates structural imperfections.

Part 2 — Engine

Tri-Motor

Architecture

Inside the Machine — Engine

Engineering the Core

At the heart of the X1 lies a revolutionary axial-flux powertrain. Designed for immediate torque and sustained high-RPM efficiency, this tri-motor system eliminates mechanical lag, delivering pure, unfiltered acceleration directly to the tarmac.

Axial Flux Architecture

Tri-Motor AWDCompact pan-cake style motors that deliver ultra-high torque density, allowing for a powertrain 50% lighter than traditional radial flux setups.

Peak Output

1,450 HP / 1,850 NmThe combined tri-motor system generates over 1,450 HP (1,080 kW) with near-instantaneous torque delivery from zero RPM.

High-Density Windings

97% EfficiencySpecialized rectangular copper hairpin windings maximize the slot fill factor, increasing magnetic flux and overall motor efficiency.

SiC Power Electronics

900V SystemNext-gen Silicon Carbide inverters operate at high frequencies with minimal switching losses, enabling precise torque vectoring at the millisecond level.

Thermal Management

Cryo-StableDirect oil cooling of the stator and rotor ensures consistent performance output even during sustained high-load track sessions.

Direct Drive

1:9 ReductionMotors are coupled directly to the wheels via single-speed reduction gears, eliminating transmission lag and mechanical complexity.

Lightweight Housing

7075-T6 AlloyMachined from aerospace-grade aluminum alloy to provide rigid support for the rotor while minimizing unsprung mass.

Durability

Infinite DriveEngineered for a million-mile service life with sealed bearings and redundant sensor arrays for failsafe operation.

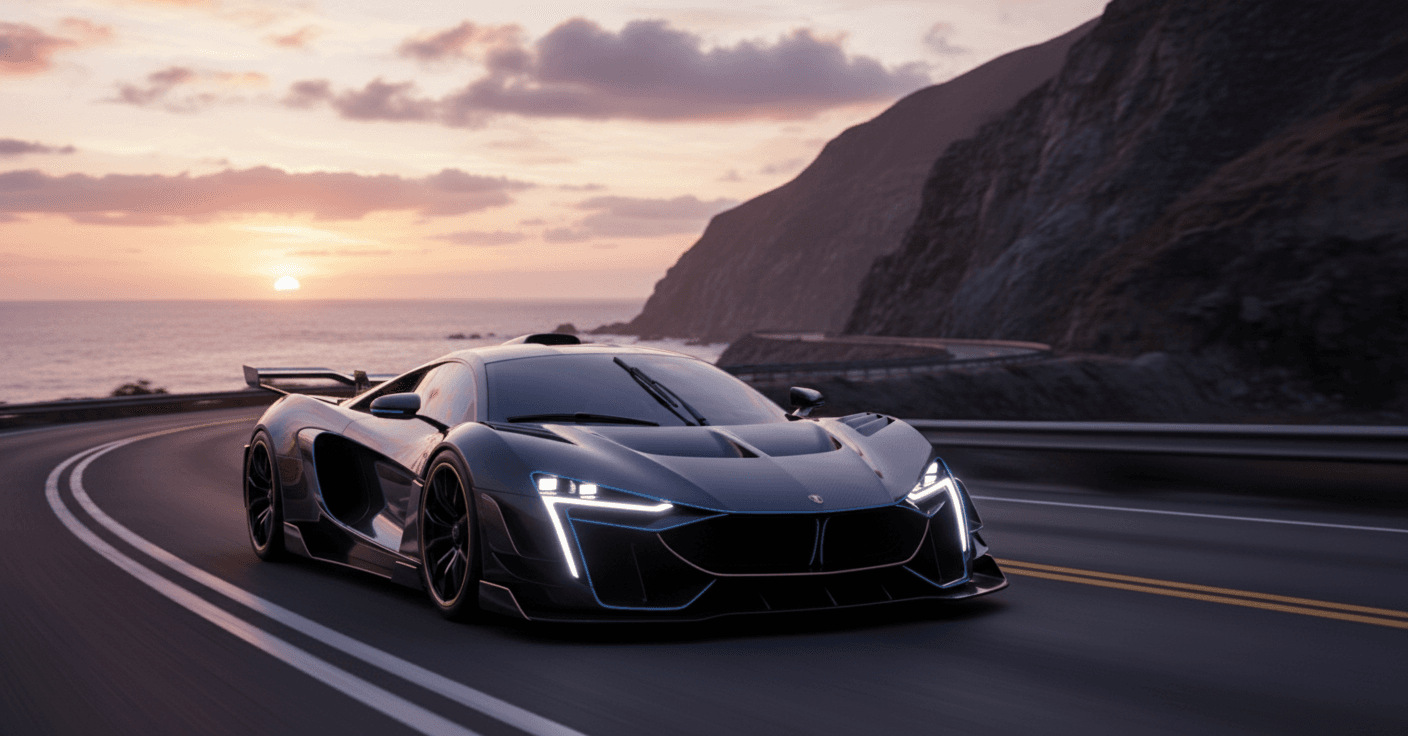

SCULPTED

Design Philosophy

Aesthetics of Speed

Design that does not apologize.

Form follows force.

Aerodynamic Form

Every curve is dictated by the wind. The X1’s silhouette is a result of thousands of hours of wind tunnel testing, ensuring laminar airflow attachment from the nose to the active rear diffuser.

Minimalist Cockpit

The interior strips away distraction. A driver-focused layout places all critical controls on the steering yoke, while a holographic HUD projects telemetry directly onto the asphalt ahead.

Material Purity

We use materials in their honest form. Exposed forged carbon fiber, cold-touch anodized aluminum, and sustainable Alcantara create a tactile environment that feels as engineered as the drivetrain.

Signature Lighting

The X1 identifies itself with a predatory laser-matrix light signature. At night, the active aero elements are subtly illuminated, turning the car into a moving sculpture of light and shadow.

Dynamic Presence

Unrelenting Speed

Nocturnal Predator

The Obsidian Philosophy

Precision is not an act.

It is a standard.

Vision

Obsidian exists to challenge the excess of the hypercar world. We do not chase numbers for marketing; we chase the purity of driving physics. Every gram of weight, every degree of camber, and every line of code serves a singular purpose: absolute connection between driver and machine.

Philosophy

Form follows force. We believe that true beauty in automotive design is the result of aerodynamic necessity. There are no fake vents, no decorative wings. If a feature does not enhance performance or cooling, it does not belong on the X1.

Engineering

Power is nothing without control. Our engineering mindset prioritizes system-level optimization over isolated peak statistics. The integration of our tri-motor powertrain with the active chassis creates a vehicle that feels organic, responsive, and alive.

Craftsmanship

We combine the precision of advanced robotics with the soul of human touch. From the laser-aligned carbon weave to the hand-stitched Alcantara interfaces, every Obsidian X1 is a testament to the uncompromising standards of modern manufacturing.

Future

The X1 is not a static object; it is an evolving platform. Through modular hardware architecture and software-defined dynamics, we ensure that the vehicle remains at the bleeding edge of performance long after it leaves the factory.

Obsidian Automotive

Est. 2026